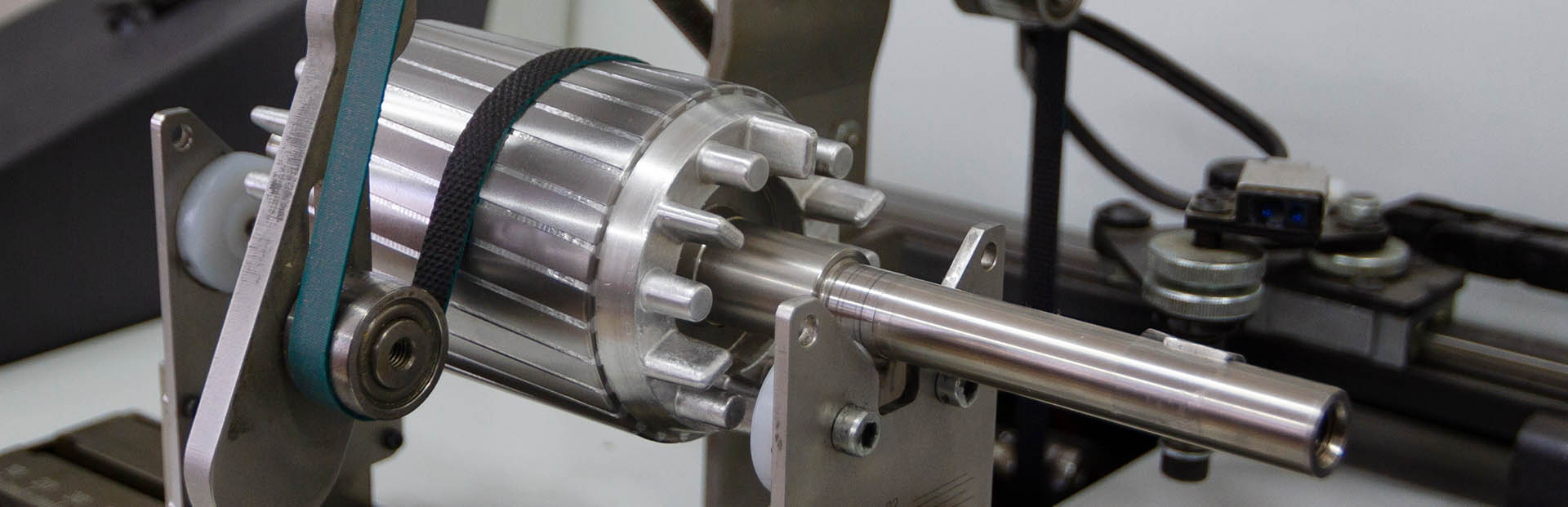

Rotor balancing

The balancing process is done by the contact method on a horizontal machine with optional setting of values in milligrams of imbalance with the objective to achieve the perfect distribution of the rotating body mass. The process itself can be set as removal of imbalance, for instance, by drilling or on the contrary by addition of material to ensure the internal distribution of the matter within the given limits. Supply of a certificate proving the value of the target imbalance is a matter of course.

| Machine designation | Type of machine | Number of machines | Dimensions |

|---|---|---|---|

Schenck | Pasio 5 | 1 | Max. rotor diameter: 150 mm Max. rotor weight: 5kg Max. speed: 5000 rpm |