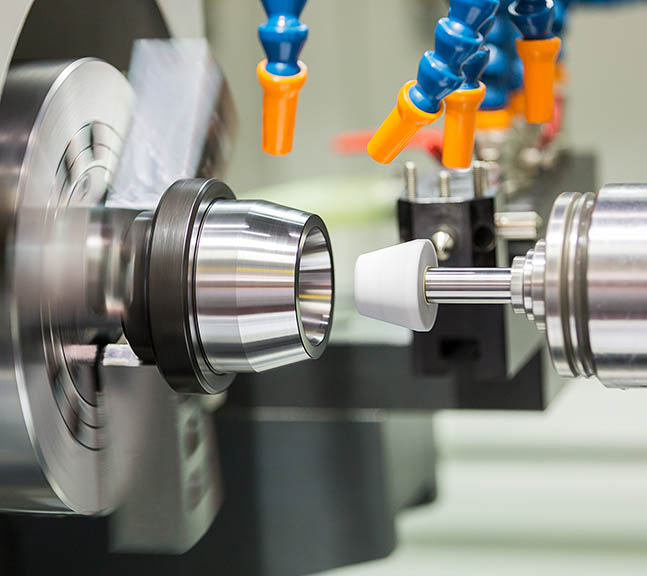

CNC grinding – circular and flat

In the case of sophisticated component shapes with a high demand for precision, we have the option to perform the CNC grinding of both rotary shapes and eccentrically positioned surfaces, inner shapes in the case of the Studer CNC rotary grinder. The production programme for grinding of non-rotary components is executed on the Okamoto grinder. The achieved component grinding precision may be up to 0.002 mm with almost a mirror appearance even on very hard materials.

| Machine designation | Type of machine | Number of machines | Dimensions |

|---|---|---|---|

STUDER | Favorit CNC | 1 | Tip distance: 650 mm Additional tip distance: 1000 mm Tip distance: 650 mm |

OKAMOTO | ACC-52SA1 surface grinder | 1 | Maximum working range of the axes (length x width) 650x230 mm Table size: 505x200 mm The distance between the disc and the table: 47,5 až 397,5 mm Dimensions of a standard magnet: 500x200x75 mm Max. table load including magnet: 200 kg |